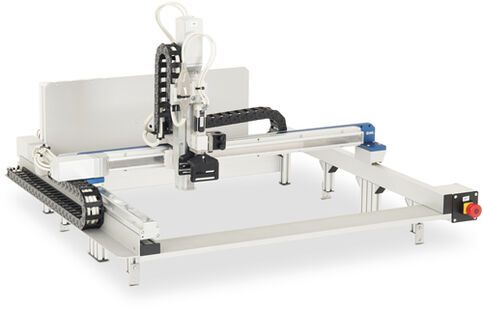

3-axis gantry robot with gripper

The portal robot can be used as a single workstation for teaching the basics. The basics are taught with the help of 5 table top project panels and an accompanying course. An expansion with IMS® transport systems is also possible. Then the portal serves as a transport crane for workpieces. It is positioned on four transport systems in a production line and can freely navigate between these four conveyor belts. A storage area on the front offers additional space to cut out the workpieces from a production process. An additional integration of the portal into the higher-level ERP system ERP-Lab is also possible and thus offers maximum complexity.

The three axes are driven by servo motors whose controllers are connected to a PLC via PROFINET. The electrical 2-point gripper is also controlled via PROFINET and can carry any workpiece up to a weight of 300g (10oz). The opening angle of the gripper is freely controllable and the force can also be individually adjusted. The gripper thus acts as a full fourth axis in the system.

Any pens can be fixed in the pen holder. The holder is attached to the gripper axis using magnets. The pen holder thus loosens automatically in the event of incorrect operation and thus prevents damage to the pen, portal or the contact surface.

- Travel axis X direction: 500mm (20")

- Travel axis Y direction: 500mm (20")

- Travel axis Z direction: 150mm (6")

- Load capacity: max. 300g (10oz)

- 24 V servo technology

- Electric 2-point gripper

- PROFINET for all 4 axes