UCP 46 Car Production with Quality Control

UCP 46 Car Production with Quality Control

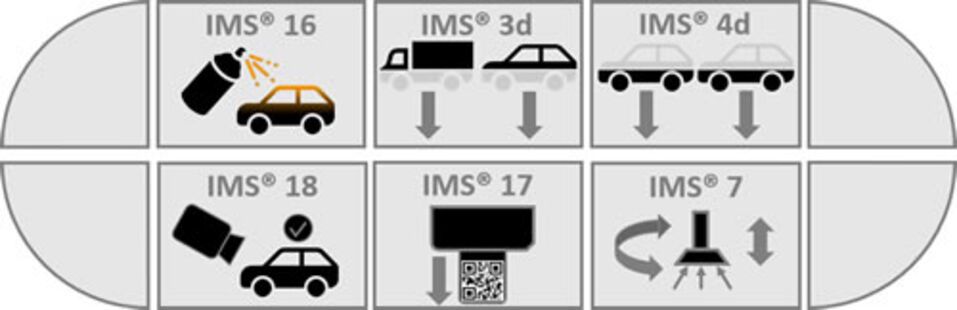

This system is used to train all of the required working steps. Starting from the conception, through the mechanical assembly of the facility all the way to the programming of a fully automated production line. The journey goes from the basic principles of individual subsystems all the way to the advanced programming and networking of entire production systems. A multi-part car with integrated operational pcbs, chassis and different car bodies is completely assembled and “painted” on a fully automated production line. Subsequently a quality control phase takes place including individual labelling. Using an imprinted QR code the production sides of the products can be called up via mobile end devices. A detailed overview of all production data can be monitored. Using a QR code and AR-capable end devices it is possible to project and observe a 3D model of the ordered product on the table.

Training content:

- Create TIA-Portal projects

- Become familiar with mechatronic systems

- Convert mechanical operations into programmable sequential operations

- PLC programming of sequential control systems

- Integration, i.e. Networking of individual systems into production lines

- Implementation of full-automated production lines

- Networking of an ERP system with the production line

Your benefits:

- Modularity of the systems

- Usage of genuine industrial components

- Self-study courses to explore and work through requirements

- Flexible project situations

- Multiple extension options Including:

- Augmented Reality

- Robotics