IMS Virtual Trainer package

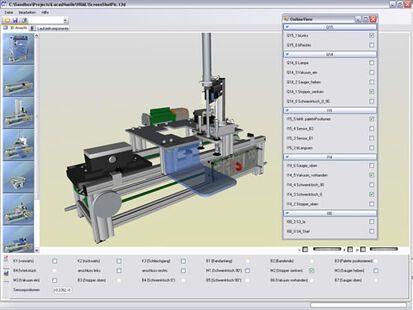

IMS® Virtual is a PC-based graphical 3D simulation system, which provides a virtual training platform for the IMS® mechatronics training system. Its virtual sub-systems and production lines are displayed in real time in the form of dynamically animated, virtual 3D scenes, in which all the components are represented. The 3D scenes are programmed just like the authentic models using STEP 7 and controlled using “PLCSIM” PLC software. The teacher/trainer version allows practically any configuration of IMS® production lines to be set up using a library of virtual IMS® models using just a few clicks of the mouse.

The training package consists of one teachers’ version and 12 student versions, which are licensed and authorised by means of a USB dongle connected to a network.

Special features:

- Process modelling and operating response simulated true to detail and graphically in 3D

- Malfunctions are simulated as they occur in actual practice in the process simulations

- Library with fully functional mechatronics sub-systems and production lines

- Real time simulation

- Collision detection

- Fault simulation: configuration of faults in sensor settings and in electrical and physical component attributes

- Parameter setting, programming and commissioning of technically different systems

- Perform systematic trouble-shooting on production facilities

- Central operation and monitoring of systems and processes

- Become familiar with function and system structure of a production system

The following stations are represented in the library and can be combined in virtually any configuration with the teachers' version of the software:

- IMS® 1 conveyor belt system, consisting of the following belt segments: passive, motorised and 180° curve

- IMS® 3 Sorting

- IMS® 4 Assembly

- IMS® 5 Processing

- IMS® 6 Testing

- IMS® 7 Handling

- IMS® 8 Storing

- IMS® 11 Disassembly using a robot

Four IMS® system set-ups are also represented in the library:

- IMS® 23 Production line with 3 sub-systems

- IMS® 24 Production line with 4 sub-systems

- IMS® 25 Production line with 5 sub-systems

- IMS® 26 Production line with 6 sub-systems

System requirements:

- Personal computer with Windows Vista/7/10 Professional operating system, .NET Redistributable 2.0 and DirectX 9.0c

- STEP7 Professional (STEP7 included in training package)

- CD-ROM drive for installation of software

- USB port for “IMS Virtual” server dongle

- Local network for license management

- At least 500 MB of available disc space

- At least 8 GB of available RAM

- CPU operating at 2,7 GHz

- Genuine 3D graphics card with at least 2 GB of on-board memory