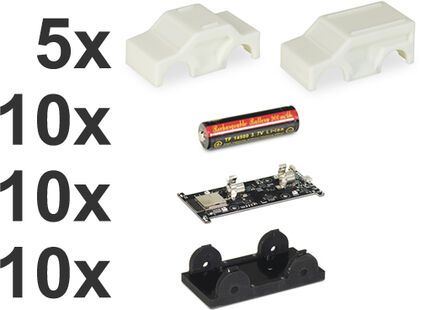

Set of cars for the production line

Set of car parts comprising chassis, car bodies, operational pcbs and batteries for a total of 10 complete cars.

Chassis:

Chassis for a complete car assembly.

The chassis has four positioning and fixing dowel pins to position the associated pcbs exactly. Two centrally mounted magnets activate the operational pcb during installation. Four magnets arranged on the outside attach it to the car body. The holes on the sides are used to mount axles and wheels typically available on the market from various component manufacturers.

Car body:

Car and van body to complete an assembled motor vehicle.

Four iron pins are pressed into the body. The two parts are held together by the magnets in the chassis.

Operational pcb:

Operational pcb with RFID tag, WiFi chip, RGB LEDs and horn function.

The pcb connects with an ERP system via an available WiFi and logs in. The pcb can use 4 RGB LEDs to display a pre-selected colour for the car (the car will be painted). Additional function LEDs serve as headlights, rear lights and indicators (blinkers). A buzzer mounted on the pcb can reproduce signal tones to simulate a horn. The controller of the pcb can be used to program and play back different melodies as horn signals.

A 3.7 V battery inserted in place can be charged via the USB socket or via two contact surfaces under the pcb. To charge via the contact surfaces, a charging tray can be used.

Technical data:

- 4 RGB LEDs

- 2 white LEDs (headlights)

- 2 red LEDs (tails lights)

- 4 yellow LEDs (indicators)

- 3 status LEDs

- 2 control buttons

- Controller

- WiFi module

- RFID tag

- Battery holder

- Integrated charge control

- Buzzer