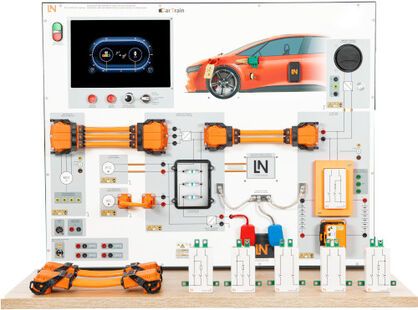

CarTrain: "Diagnosis and Repair of HV Vehicles" and "ASE L3 Trainer Light Duty Hybrid/Electric Vehicle Specialist"

The CarTrain "Diagnosis and repair of HV vehicles" combines hardware with interactive e-learning and offers the ideal introduction to high voltage technology. It fully meets the requirements of the ASE L3 Light Duty Hybrid/Electric Vehicle Specialist Test and other internationally recognized qualifications.

Special features of the training system:

- Practical learning projects by transferring the complete action model to workshop situations

- Comprehensive testing of system main relays:

- Three relay types: HV+ pre-charging, HV- pre-charging and pre-charging by DC/DC converter via 12V battery with testing of functional and defective relay assemblies in dismantled condition

- Testing for welded relays

- Replacement of faulty relays (energized)

- Working with real high voltage: 400V system voltage, protective impedances ensure maximum safety

- All common methods for vehicle isolation such as:

- High voltage service disconnect on HV battery

- 12 V service maintenance plug

- Emergency low-voltage disconnection point and fuse

- Scan tool guided isolation

- Live-Dead-Live-Testing

- Real repair processes supplemented by defective components included in the delivery:

- Defective high voltage fuses

- Defective 3-phase cable harness

- Defective DC wiring harness

- Defective air conditioning wiring harness

- 6 relay modules (1 each for fault switching and 1 as a spare part for each pre-charging variant)

- Defective potential equalization cable

- Acoustic warning in the event of serious operating errors, e.g. opening the interlock

when the high voltage system is active (can be deactivated)

- Testing the potential equalization on real metal components

- Simulation of abnormal noises due to magnetic interference

- Touchscreen with virtual cockpit and HDMI output

- With power meter and energy flow analysis for various hybrid and electric vehicles, including fuel cells

- Integrated tester with fault diagnosis and live data streaming

- Use of test adapters for measuring motor and insulation faults

- Real HV signal measurements:

- High voltage voltages and currents in the HV system in all driving conditions

- Communication with charging stations

- Motor position sensors (resolver and Hall effect)

- DC/DC converter for 12V system

- Jump start for high voltage vehicles with faults in the 12V system

Scope of delivery:

- Training system "CarTrain Diagnosis and Repair of HV vehicles"

- Project case with spare parts and work materials

- Type 1 charging cable (J1772)

- Operating instructions

- Interactive learning software

Manufacturer independent vehicle configuration:

The vehicle configuration can be flexibly customized by replacing the main relays and adjusting the drive concept.

The following drive concepts are available:

- Standard hybrid drive with plug-in

- Parallel hybrid drive with plug-in

- Series-parallel hybrid with plug-in

- Electric vehicle

- Fuel cell vehicle

Structure of the training system:

- 12.1" touch panel with virtual cockpit and integrated diagnostic tester. Display output possible via HDMI.

- Replaceable system main relay with safety cover including interlock

- 12V jump-start point

- Display of HV auxiliary units such as air conditioning and PTC heating

- Display of various drive concepts on ePaper display

- Smart key for activating the vehicle

- Rotary dial for controlling the vehicle speed

- Switch for controlling the driving profile between incline, flat and downhill

- Start and brake button to switch on READY mode

-

- Real HV fuse from the vehicle

- Quick-release battery terminals for tool-free removal of the battery terminals

- Metal components for measuring the potential equalization

- Isolation variations:

- Emergency low-voltage cutting point and fuse

- HV service plug

- 12V service plug

- Measuring points to verify the absence of voltage behind metal cover with interlock contact

- Safety measuring sockets with protective impedances for the safety of trainees

- Type 2 charging port for connection to a charging station

- Charging activation switch

Integrated measuring interface:

- Connection via USB

- Diagnostic scan tool

- 4-channel oscilloscope

-

- Four voltage inputs up to 600V AC/DC

- Voltmeter

-

- Saving oscilloscope images in e-learning via copy & paste

Practical training content:

- Correct selection and testing of suitable measuring and testing equipment

- Applying service information

- Carry out service work on the HV system

- Charging the HV battery

- Measurement of equipotential bonding cables

-

- Various methods for unlocking the vehicle:

- High voltage service disconnect on HV battery with live-dead-live test

- 12V service plug

- Emergency low-voltage disconnection point and fuse

- Tester-guided activation

-

- Commissioning of an HV system

- Insulation tests and winding measurements with test adapters.

- Insulation test for HV cable, AC compressor and drive motor faults

Course contents:

The scope of delivery includes an interactive training course with practical project work.

This covers the following topics, among others:

- Basics of high voltage vehicles:

-

- Term "high voltage"

- Types of hybrid and electric vehicles

- Operating modes of hybrid and electric vehicles

- Basics of high voltage technology and drives in motor vehicles

-

- Voltage level in vehicles

- Cell chemistries of high voltage batteries

- Temperature control of high voltage batteries

- Safety systems in high voltage vehicles and HV intrinsic safety

- Isolating and reactivating of HV systems

- Types of electrical machines

- Motor position sensors in drive motors

- Power electronics and voltage conversions

- Regenerative braking

- Control of electric drives

- Charging electric vehicles and communicating with charging infrastructure

- Safe handling of high voltage vehicles:

-

- Occupational safety

- Dangers from high voltage systems

- Current paths through the body

- Selection and inspection of PPE

- Safe working on high voltage vehicles

- Dealing with damaged HV vehicles

- Release points and safe handling of vehicles for first responders and emergency services

- Diagnostics and maintenance work on high voltage vehicles

-

- Troubleshooting electric motors

- Jump start for high voltage vehicles and troubleshooting on the 12V charging system

- Localization of insulation faults

- Correct implementation of potential equalization measurements

- Checking the shielding and magnetic interference faults

Dimensions and power supply:

- Power supply: AC 120V, 60Hz / 3A

- Dimensions: 1000x800x220mm, 39"x32"x9" (WxHxD)

- Weight: approx. 38 kg, 84 lbs