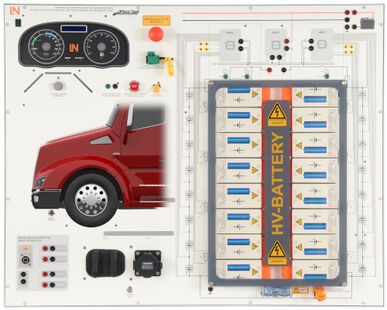

TruckTrain "Diagnosis and Repair of a HV Battery"

The continuous development of electric mobility also presents new challenges for the commercial vehicle industry. Especially the HV-battery has the greatest potential for danger, especially during repairs.

This poses new challenges and requires a special understanding of the system so that proper work is possible here as well. Our training system focuses on the digitally networked CAN bus battery management system in the traction battery and the associated components.

Especially the measuring and functional testing of live high-voltage components was implemented here. The battery cells are measured and diagnosed under voltage in a practice-relevant manner. The HV battery is designed in such a way that it can be disassembled to replace individual cells and sensors. In this way, the HV battery is diagnosed and repaired in an action and practice-oriented manner.

The HV battery is constructed in such a way that it can be disassembled in order to replace individual cells and sensors. In this way, the HV battery is diagnosed and repaired in an action and practice-oriented manner. Particular focus is placed on system-critical situations that can occur in the event of a malfunction in the hybrid and electric vehicle. In particular, faults are dealt with that occur on the vehicle but cannot be worked through independently during training. This includes not only the HV system and its control and protective devices, but also critical faults in the energy storage system itself. Diagnostics can be started in a practical manner using the integrated diagnostic tester. The diagnosis can be further deepened with the integrated and workshop-standard HV measuring equipment. This includes not only measurable faults in the HV safety systems, but also faults in the temperature sensors and battery cells, the practical replacement of which can be carried out. In this way, a qualification level for working in energy storage systems is also achieved.

Outstanding functions of the training system

- Precharge and main relays with self-diagnosis function and provided with fault circuits.

- 16 battery modules, individually replaceable, digitally coded, provided with fault circuits.

- 8 battery temperature sensors, replaceable and provided with fault circuits.

- Pilot line with diagnostic function and provided with fault circuits

- Hall-effect current sensor for contactless measurement of charging and discharging processes

- Real battery cell balancing with live data transmission to the diagnostic tester

- Visualised display of the selected driving profile

- Bidirectional energy flow display between drive and HV battery

- CCS type 2 fast charging socket for DC and AC charging

- Energy flow visualisation from charging ports to HV battery

- Digitally networked CAN bus battery management system with measurement interface

- CAN bus test sockets (3-fold, for signal tracking in the event of a fault)

- 50 fault switching options in the HV system and in the HV battery

Scope of delivery:

- TruckTrain CO3221-7E "Diagnosis and repair of a high-voltage battery

- Interactive course on data carrier with Labsoft browser, course software and additional virtual instruments

- Integrated diagnostic software

Digital measuring instruments:

- Digital networked measurement capability

- 4-channel oscilloscope

- Voltmeter

- Ammeter

- Double voltmeter

- Performance measurementer

Learning contents:

- Trace customer complaints, carry out functional checks and define diagnostic paths

- Reading the error memory

- Assessing work safety

- Testing the effectiveness of electrotechnical protective measures on the high-voltage system

- Replace high-voltage components

- Get to know the position of the components in the vehicle

- Determine faults and their causes with the aid of circuit and function diagrams

- Create test protocols and document results

- Take measures to prevent hazards due to insulation faults

- Know data communication between the control units

- Identifying and carrying out repair possibilities

- Determine diagnostic and repair options depending on the customer order

- Determine system statuses with the aid of diagnostic systems, compare them with information in databases and evaluate the results

- Measuring and testing on systems

- Determine target data

- Select measuring method and measuring instruments

- Document measured values

- Recording measured values, comparing them with target data and evaluating them

- Measuring, testing and evaluating signals on components and systems

- Measuring, testing and evaluating electrical connections

- Check high-voltage systems with diagnostic equipment, in particular carry out insulation, equipotential bonding and voltage drop measurements

- Analyse and evaluate messages in data bus systems

- Structure and function of battery cells in the HV battery

- Design and function of temperature sensors in the HV battery

- Design and function of HV charging systems

- Advantages and disadvantages of individual HV charging systems

- Measurement options for power consumption with different driving profiles in practice

- Measurements of the voltage curve in the HV battery at different charge and discharge cycles

- Interaction of sensors and actuators

- EVA Principle

Components of the experimental system:

- Power switch

- Emergency stop safety switch

- ignition switch

- Control unit BMS 1

- Control unit BMS 2

- Central control unit for BMS1 and BMS2

- Precharge and main relay with self-diagnostic function

- 16 battery modules, exchangeable, digitally coded, equipped with error circuits

- Active - battery cooling

- 8 battery temperature sensors, exchangeable

- Pilot line with diagnostic function

- Hall-effect current sensor for non-contact measurement of charging and discharging processes

- Real battery cell balancing

- Selectable driving profile

- Slope

- Level

- Sailing

- Slope with recuperation

- Electric braking with recuperation

- Visualised display of the selected driving profile

- Low Voltage Service Disconnect

- High Voltage Service Disconnect

- HV-safety for rescue services

- Instrument cluster with

- Powermeter power display

- Speed display

- Battery charge level indicator

- HV-Ready and EPC warning light

- Charging station indicator light

- Warning light for power limitation

- Rotating drive wheel

- Bidirectional energy flow display between drive wheel and HV battery

- Type 1 charging socket for AC charging

- CCS-Type 2 quick charging socket for DC and AC charging

- Charge button to control the start of charging

- Energy flow visualisation from the charging sockets to the HV battery

- 2mm and 4mm safety measuring sockets

- Removable total battery cover

- Contact protection covers for the battery cell connections

- Digitally networked CAN bus battery management system with measuring interface

- Test sockets for temperature sensors

- Test sockets CAN bus

- Test sockets HV

- Test sockets battery module 1

- Test sockets battery module 2

- Test sockets 12V

- Connections for potential equalisation measurement

- Terminal designation according to DIN 72552

- 46 Error switching options

- USB connection socket

Supply voltage:

Operating voltage:

Dimension: